Ph: 1300 01 TRIP

Tramp Metal Detector

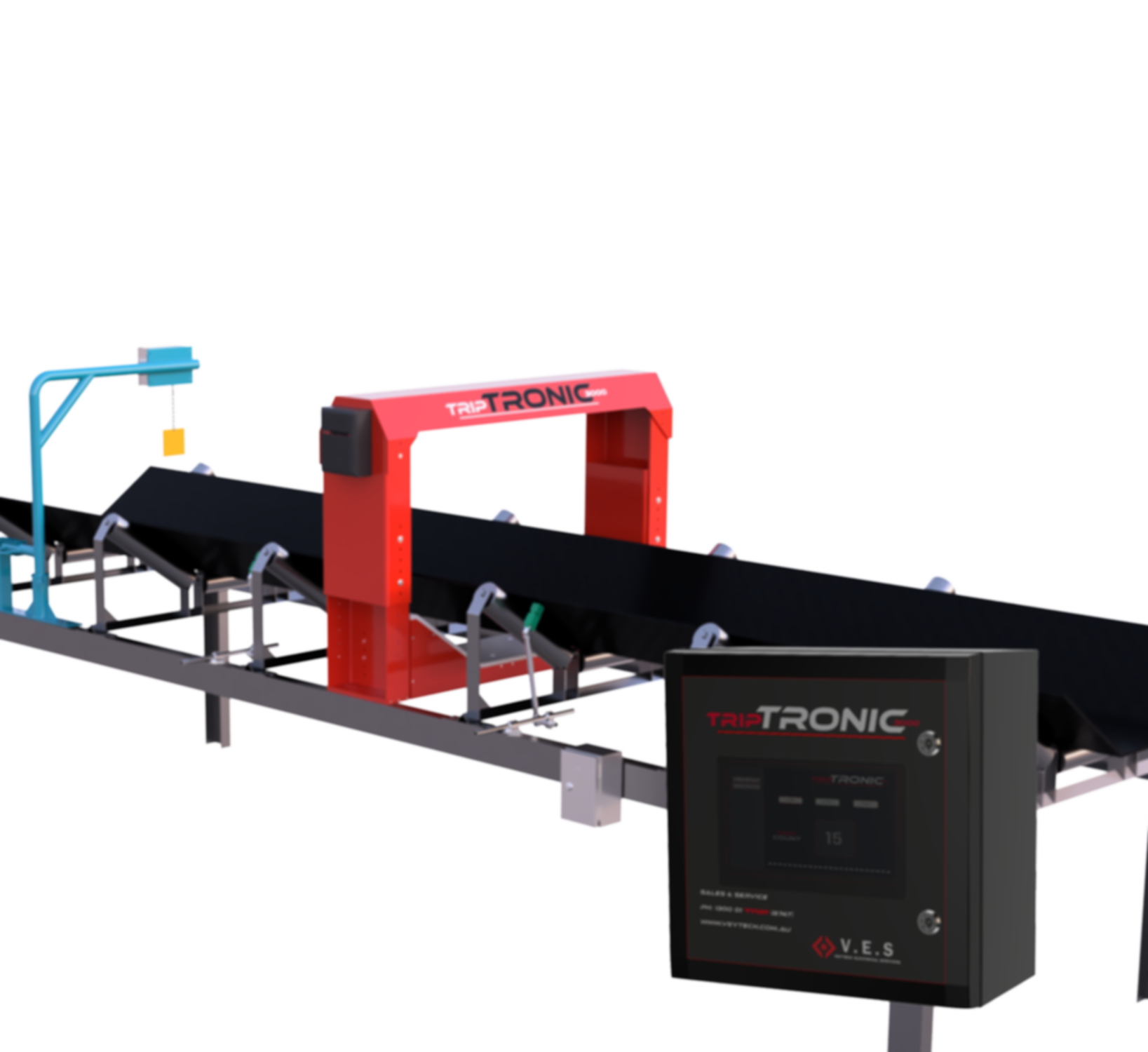

The TripTronic 3000 is an advanced tramp metal detector for conveyor belts, designed to safeguard assets and maximize efficiency in demanding mining environments. With reliable, accurate detection capabilities. Specifically engineered for high-magnetic ores and high speed conveyor, this advanced system prevents costly damage and ensures smooth, uninterrupted production. Its user-friendly interface and robust design make the TripTronic 3000 an essential solution for maintaining asset protection, efficiency, and peak operational performance.

Enhance Your Operation with the TripTronic 3000

How It Works

The Trip-Tronic tramp metal detector detects the metal by generating a pulsed electromagnetic field from the transmitter coil, known as the primary electromagnetic field. This magnetic field produces an output signal from the receiver coil.

When a piece of tramp metal passes between the coils into the pulsed electromagnetic field, small electrical currents loops known as eddy currents, are induced in the metal.

The pulse from the transmitter coil is turned off momentarily, and eddy currents induced in tramp metal produce a secondary magnetic field. This new field also produces an output signal in the receiver coil. The Trip-Tronic controller measures the effect of this secondary magnetic field only during the time the primary field is inoperative. The material on the conveyor belt also produces a secondary magnetic field. The two magnetic fields can be distinguished from each other by observing their decay times. The better the conductivity characteristics of the material, the longer the decay time. As the magnetic field decays, the output signal strength decreases

The Trip-Tronic is designed to take advantage of the difference in decay time by activating its measurement window (the point at which it reads the output signal) only after the magnetic field from the material on the conveyor has decayed and before the tramp's decay has ended. Using this measurement window timing helps prevent both false trips and passed tramp metal.

Specifications

Touch Screen

Screen Size:

Number of Pixels:

Display Area:

Display Mode:

Surface Treatment:

Interface:

Backlight:

Operating Temperature:

10.1 Inches

1024 RGB

222.72 X 125.28

Black / Transmissive

Anit Glare

RGB

LED Side-light type

-20°C - 70°C

Controller

Opperating Temperature:

Enclosure Rating:

Humidity:

Operating Speed:

Input Voltage:

Input Frequency:

Power:

Pulse Power:

Output Power:

Memory:

-40°C to + 80°C

IP66

10-95%

0.05 - 9.5m/sec

90 - 264 VAC

48 -662 Hz

480W

6 Amps

24VDC / 240VAC

2 x External Flash

Frame

Frame Size:

Frame Height:

Frame Width:

Material:

Coil Construction:

Coil Resistance: Balance Actuator Motor:

Balance Actuator:

Balance Actuator Rating:

Operating Temperature:

Balance actuator Max Load:

700 - 3000mm Belt Width

1060mm - 1560mm

460mm

Polyvinyl Chloride

Copper wound incased in PVC housing.

Transmitter 1.8 - 2.8 OHMs Receiver 450 - 500 OHMs 24VDC

2.5 Amps

IP65

-25°C - 65°C

3000N

A

B

C

D

E

G

H

F

Components

A. Metal Detector Frame & Coils

The Metal Detector Frame is an adjustable support system that securely holds the transmitter and receiver coils, enabling precise coil distance adjustments to optimize metal detection. Designed for versatility, it accommodates various burden depths and belt configurations, including 35° and 45° troughing angles, flat setups, and 3, 4, or 5-roll idler frames. This flexibility ensures maximum detection accuracy across different conveyor layouts, enhancing operational reliability.

B. Controller

The Trip-Tronic Controller offers a user-friendly 10-inch touchscreen graphic interface, streamlining navigation with easy-to-use menus and icons for simplified setup and calibration. This robust controller operates in extreme temperatures from -40°C to +80°C and features an IP66-rated enclosure, ensuring durability in demanding environments

C. Balance Actuator

The Balance Actuator enables automated balancing of the transmitter coil, a crucial feature for maintaining accurate tramp metal detection. By balancing the metal mass on either side of the TMD frame, the actuator ensures precise and consistent detection, optimizing the system’s performance and reducing false readings.

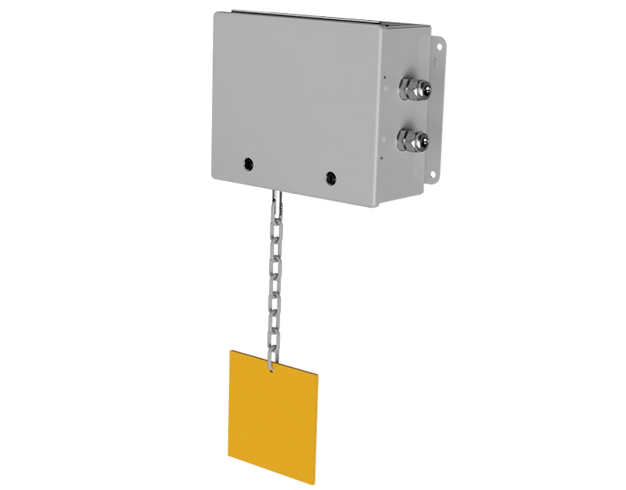

D. Flag Drop Marker

The Flag Drop Marker provides a clear visual indication of tramp metal location on the conveyor, enhancing precision in identifying contaminated areas. By setting a timed delay, it aligns with the tramp metal detector (TMD) to account for the exact duration it takes for detected metal to move from the metal detector coils to the Flag Drop device. This ensures accurate marking of the tramp metal in the burden, improving asset protection and operational efficiency.

E. Flag Drop Marker

There are two mounting frame options for the Flag Drop Marker. The Standard Fixed Frame mounts to the stringers on each side of the conveyor belt but restricts flag reinstatement on wider belts. For better accessibility, the Swing Arm Frame is recommended, as it allows the marker to swing over the walkway, making it easier for operators to reset the flag.

F. Clip Detectors

Clip Detectors are used to temporarily deactivate the metal detector to bypass the mechanical joint, or "clip," in the conveyor belt. Clips can also serve a purpose in certain repairs, however, most heavy mining operations prefer hot vulcanisation for belt joining and repair, reducing the need for clip detectors. This targeted deactivation prevents false alarms, allowing the metal detector to focus solely on genuine tramp metal.

G. Sounder / Beacon

The Klaxon nexus series DC flashy sounder 5J Xenon beacon is a powerful sounder and high output beacon with an amber lens. It has a high sound output of 110dB. This product has separate connections for sounder and beacon. The head of the sounder beacon is fixed by quarter-turn fasteners to eliminate the need for four individual screws. This enables faster installation and accurate seal compression for weatherproofing. It is a very useful innovation with the effective audio-visual signal, designed for industrial applications.

H. Calibration Arm

Veytech Engineering Services has developed an advanced automated TMD calibration device, prioritizing safety by eliminating critical entanglement risks. Powered by a 240V stepper motor and gear arrangement, it enables up to 160° of controlled rotation at various speeds, allowing the frame to swing from its home position along the stringer and pass through the TMD’s detection field at the same speed as the belt, before returning to its home position. Constructed with reinforced fiberglass, the frame includes an interchangeable metal test piece at the end to effectively simulate tramp metal. Housed in a durable stainless-steel enclosure, the device is microcontroller-driven, featuring a start button and adjustable speed control for precise calibration, ensuring both operational accuracy and operator safety.